Equipment & Technology

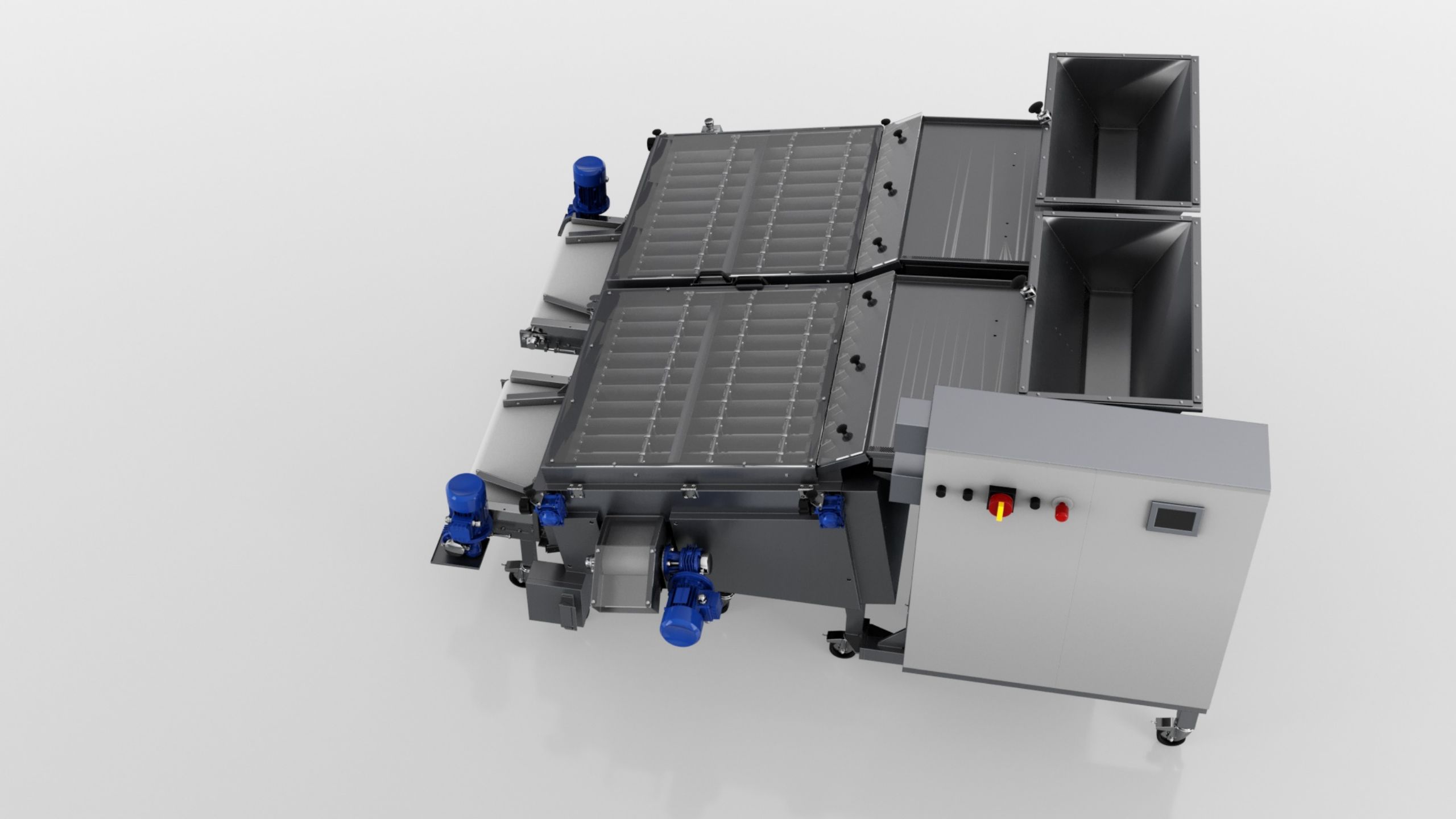

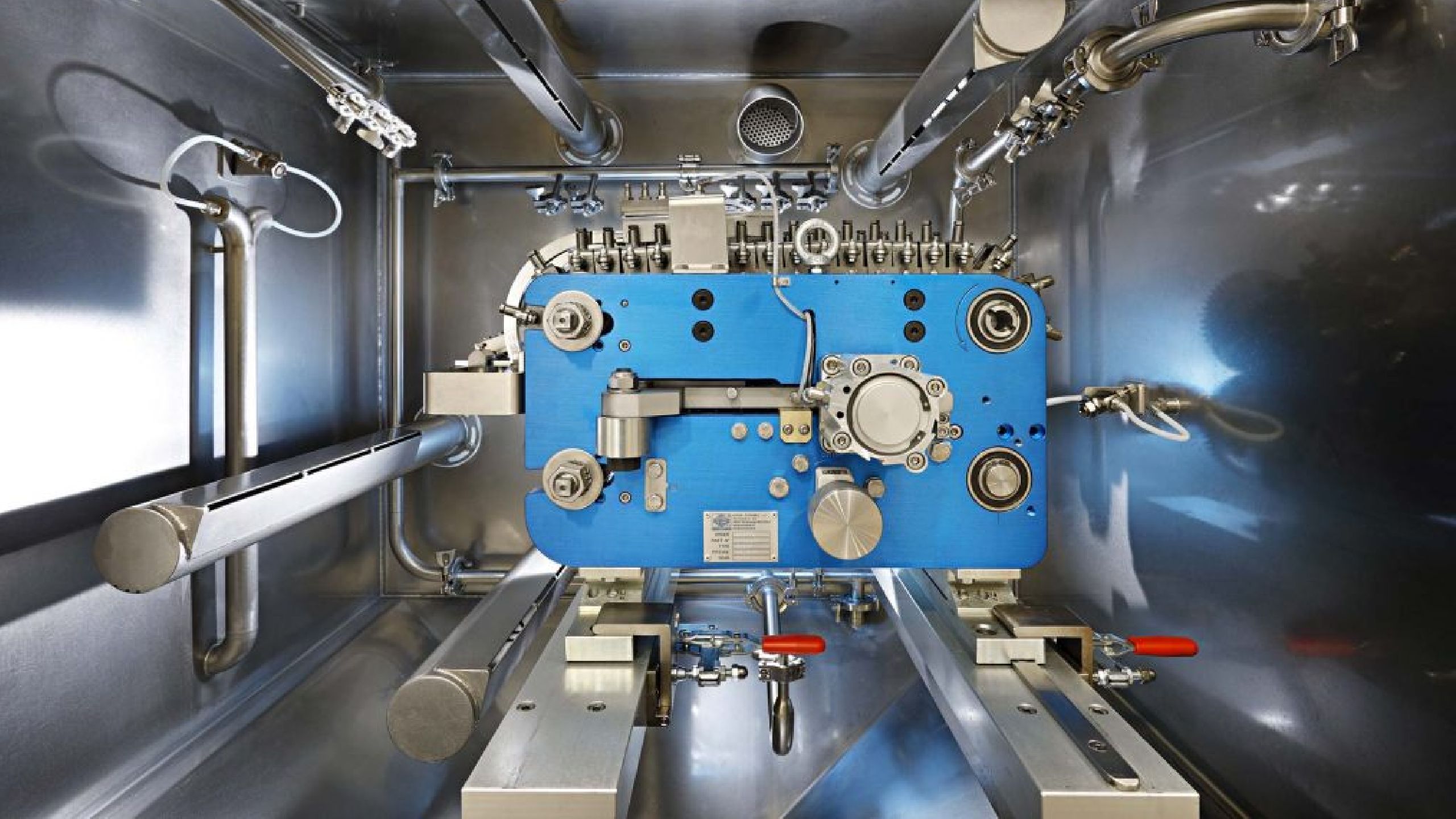

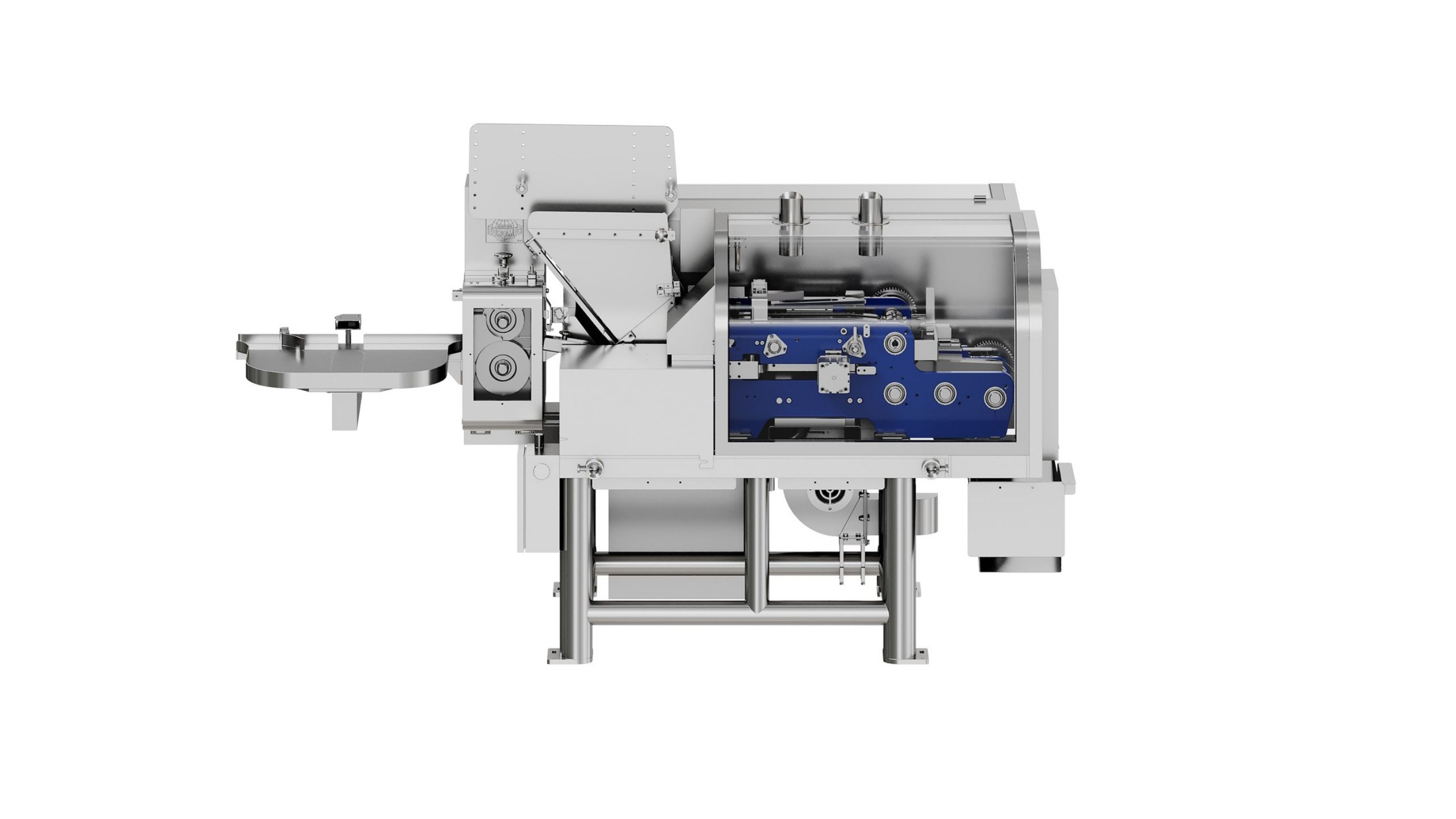

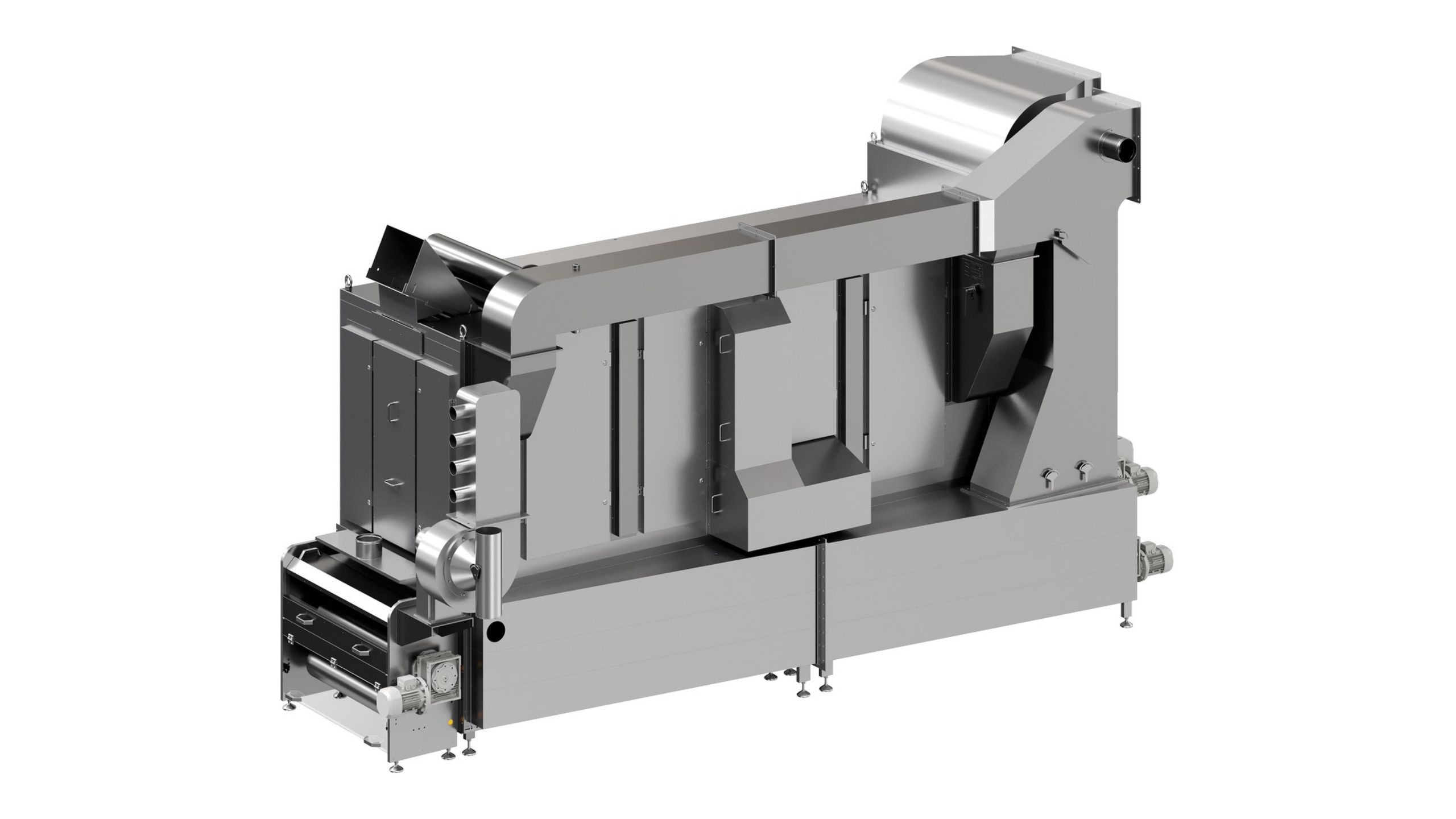

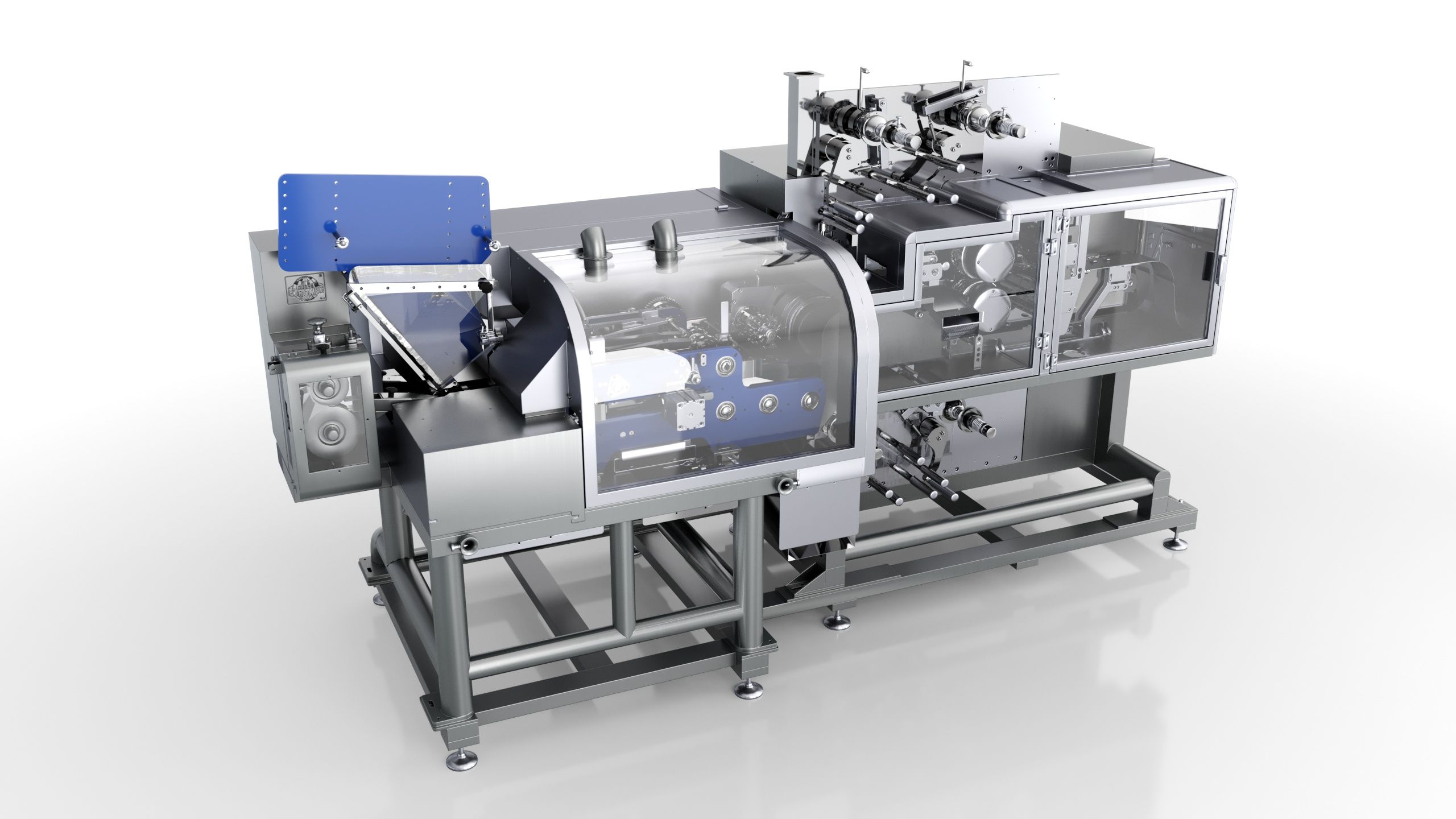

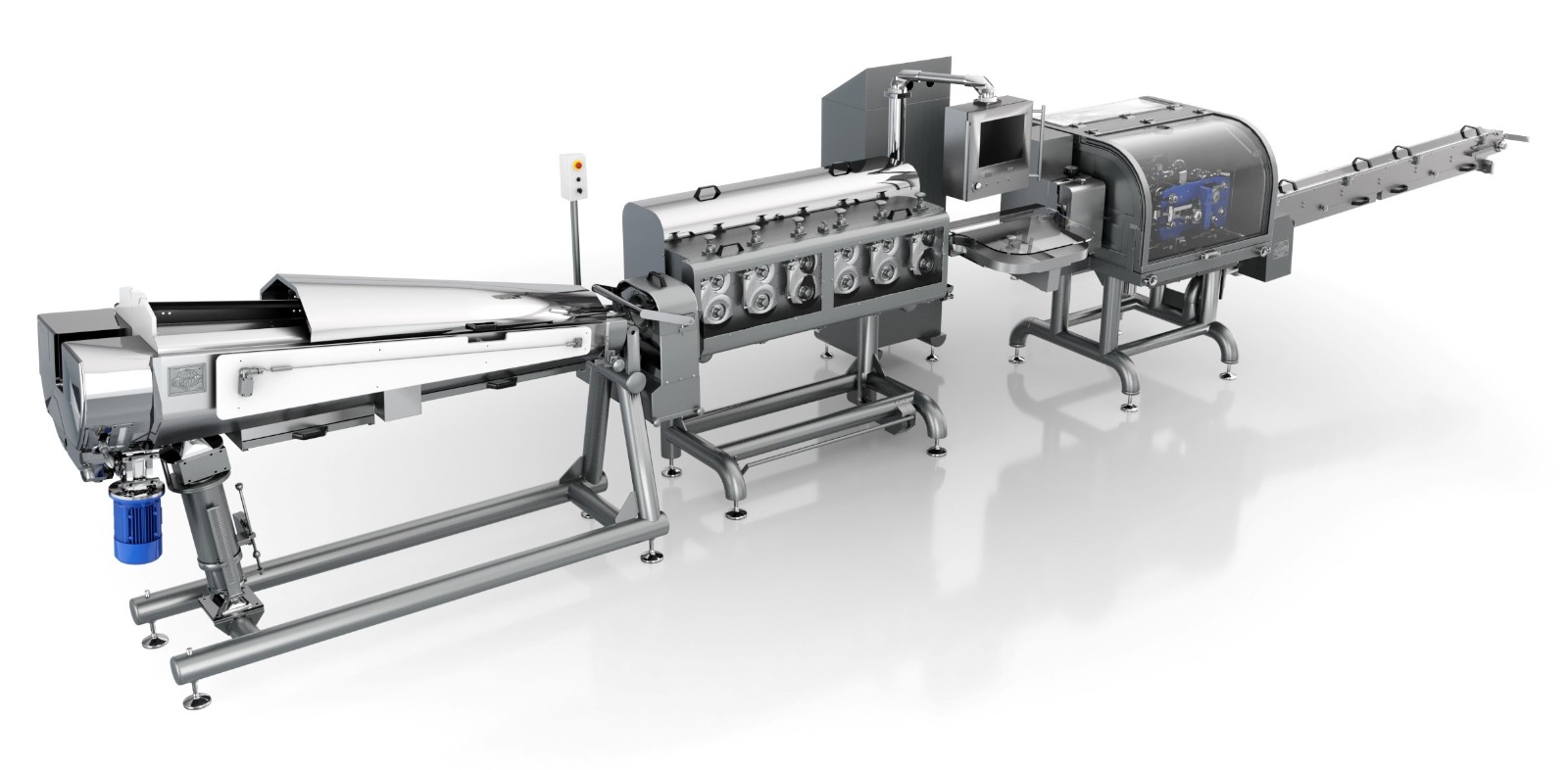

PROCESSING AND FORMING EQUIPMENT

From the initial idea to installation and beyond, Nuova Euromec has been supplying state-of-the-art processing and forming equipment for over 40 years, together with best-in-class technical support in the field.

Our goal is to deliver the most efficient, long-lasting, and flexible production processes for each of our customers.

RESEARCH AND DEVELOPMENT

Bringing a new and innovative idea to life in the confectionery market means combining product chemistry with machine engineering to make a concept scalable for industrial production.

Achieving such a result requires experimentation and testing. For this reason, Nuova Euromec offers its customers the opportunity to work with us at Francesco Rizzi Lab — a fully equipped facility with a dedicated team, designed to provide the best possible support during the product prototyping phase.

WHO WE ARE

Founded in 1981 by Francesco Rizzi, Nuova Euromec has always been a family business, dedicated to continuous improvement and steady growth within the confectionery industry.

Today, our machines produce candies, lollipops, chews, gums, (and countless variations of each of them) in more than 74 countries worldwide.

This success is made possible thanks to our passion for the product and our problem-solving mindset, driven by teams that always put our customers first.